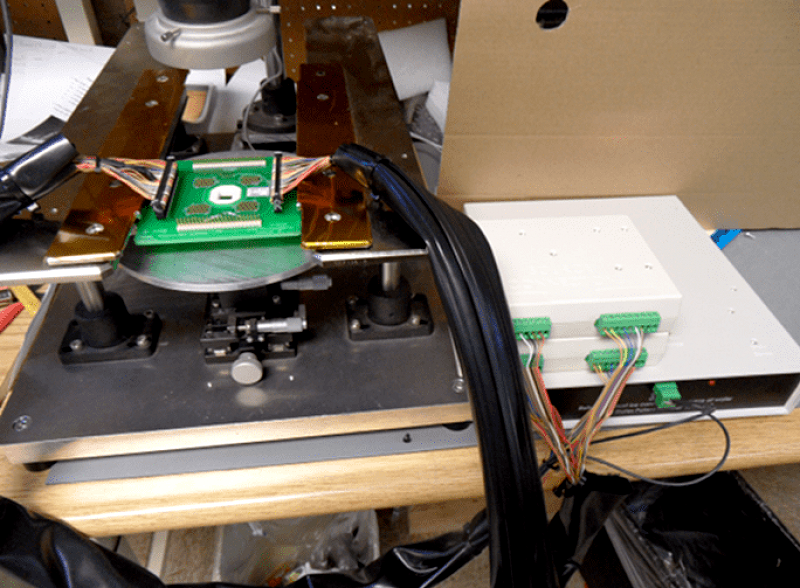

Wafer Probe System (WPS)

ITC55WPS1002 – Needle Control System

- Works with standard ITC55100 systems

- Limits Current in each probe

- Contact Resistance checks per probe

- Bad probes can be disabled

- Control software with wafer mapping available

- Ideal solution for characterization

Crowbar

Parallel Energy Path (Crowbar) – Patent Application Pending

- Parallel energy path triggered by breakdown voltage drop during avalanche test

- Provides protection to DUT and probe card during production wafer probe, reduces “debris” on wafer

- Limits DUT damage to allow better FA

- Standard on ITC75100 and ITC75300

- Optional on all ITC55XXXC model testers

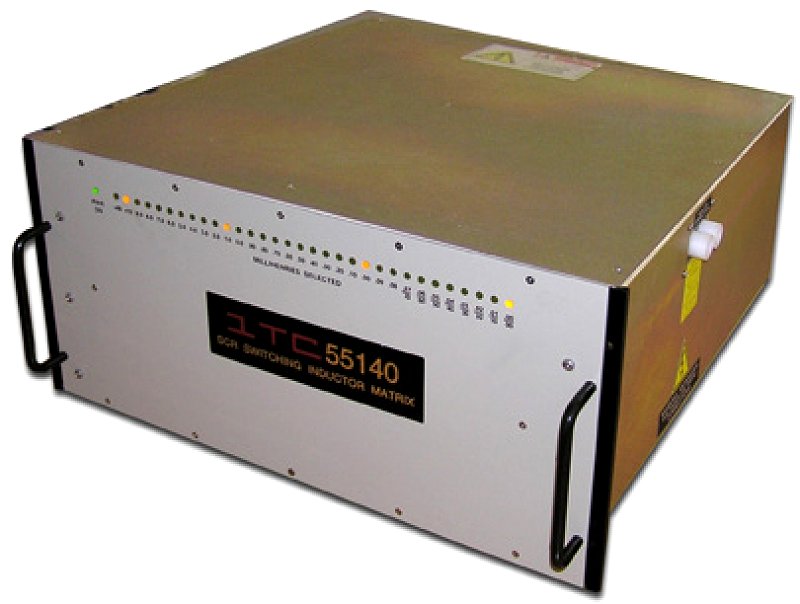

Load Boxes

Seven models of External Inductor Boxes are available:

- ITC5514A:Manually selected inductance: 0.01 to 159.9mH (200A/2500V)

- ITC5514B:Automatically selected inductance: 0.01 to 159.9mH (200A/2500V)

- ITC5515: Automatically selected inductance: 0.1, 0.3, 1.0, 3.0 and 10mH (200A/2500V)

- ITC5516: Automatically selected inductance: 0.001 to 0.300mH (400A/2500V)

- ITC55140:Automatically selected, high speed switching, inductance: 0.01 to 159.9mH (200A/1500V)

- ITC5517: Automatically selected inductance: 0.01 to 79.9mH (200A/2500V)

- ITC55170:Automatically selected, high speed switching, inductance: 0.01 to 79.9mH (200A/1500V)

Current Limiters for Wafer Probe

ITC has developed simple, low-cost modular current limiters to limit the maximum current flowing in any individual probe needle on a probe card during wafer UIL testing. The limiters are designed to be used with all ITC55100 and ITC55300 test systems and are covered by US patent # 7,521,947.

The current limiter modules are available for either source or drain connections and are factory set to a fixed current, which is most commonly 5A/probe.

The current limiters are provided in a 16 channel module which is plugged into a base module. The number of channels available can be increased in blocks of 16. Each additional block of 16 channels is plugged into the previous module.

In the case that an individual channel goes into an overcurrent condition a safety circuit in the base module removes energy from the probe card and the device under test (DUT).

High Voltage & High Current Test Solutions

The rapid innovations and developments within the semiconductor industry in general have also been very apparent within the power device sector of the industry. The move to Silicon Carbide (SiC) power devices has resulted in higher breakdown voltages for discrete devices which in turn requires the UIL test solution to have a higher voltage capability.

ITC, as the world leader in UIL test solutions, has developed 4000V/200A UIL test systems on both its 55 and 75 series testers. The ITC55100C-2HVN and the ITC75100-2HVN are both N-channel only systems with the 4000V/200A capability.

Another growth area for discrete power semiconductors is the development of higher current devices. In addition to its industry leading 2500V/200A UIL test systems ITC already had 2500V/400A systems and has now added to its product portfolio 2500V/600A versions of the test system.

The ITC55600C and the ITC75600 are N-channel only systems with 2500V/600A capability and both have ITC’s parallel energy path hardware installed to protect the DUT and test fixture during an avalanche failure.

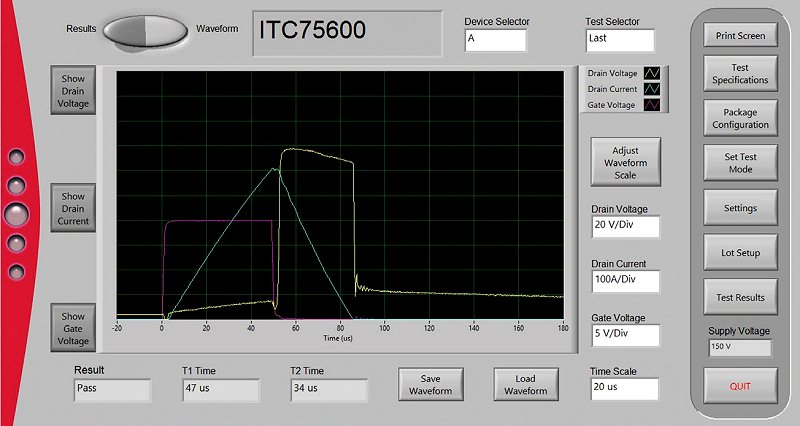

Dynamic Production Tests

ITC has added dynamic production testing capability to the ITC75100 test system. The system was already capable of testing the UIL capability and reporting the Rdson value of power semiconductors.

This new development has added several more tests to the system. These Include:

- Inductive Switching Time (LSW) tdon, tdoff, tr, tf, Eon, Eoff.

- Gate Charge (Qg)

- Qg(th), Qg(on), VgPlat, Qgs, Qgd

- Clamped Inductive Load (CIL)

- Vclamp 500V to 2000V (programmable)

- Reverse Bias Safe Operating Area (RBSOA) Vclamp 500V to 2000V (programmable)

These additional tests require a processing unit containing a single board computer and digitizer, a logic controller for setting various test parameters, a High Voltage programmable clamp and a remote POD situated close to the device under test to provide gate drive, signal conditioning and the final stage of the clamp.

These additional tests are fully integrated into the ITC75100 user interface and test software providing the user with simple, easy to understand test program set-up plus integrated results for all tests run on a device.